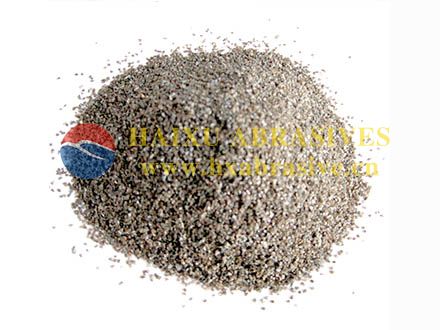

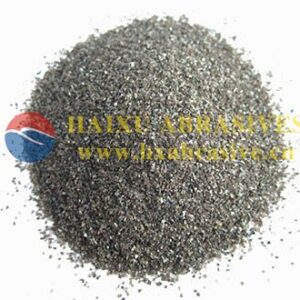

Brown fused alumina is made of high-quality bauxite, anthracite and iron filings. It is cooled and smelted in a high temperature by more than 2000 degrees in an electric arc. It is crushed and shaped by a jaw crusher and a ball mill. After magnetic separation, then sieve separated to get various kinds. Its compact texture, high hardness, suitable for the manufacture of ceramics, grinding of high tensile metal and grinding, polishing, sandblasting media, precision casting, etc., can also be used to produce advanced refractory materials.

Application:

Brown fused alumina is widely used as a raw material in many industries:

- F-grit for bonded abrasives such as resin bonded grinding wheels, vitrified grinding wheels

- P-grit for coated abrasives such as sandpaper, sanding belts

- Blasting media, metal preparation

- Laminates, coatings, lapping, polishing

- Anti-slip applications like floor, ceramics, auto brake parts

The difference between F-grit and P-grit abrasive grains:

F-grit is more suitable for bonded abrasive tools.

P-grit is more suitable for coated abrasive tools. It is with a closer tolerance size distribution, lower density, and better self-sharpening ability than non P-grit abrasives, which means that they offer a more consistent surface finish.

| Typical Chemical composition(F60) | |

| AL2O3 | 94.50% |

| Fe2O3 | 0.35% |

| Si2O | 1.40% |

| Ti2O | 3.00% |

| LOI | max0.09% |

| Magnetic content | / |

| Typical physical properties | |

| Basic minerals: | Al2O3 |

| Hardness: | Mohs 9.0 |

| Melting Point: | 2200 ℃ |

| Maximum service temperature | 1850℃ |

| Specific Gravity: | 3.95g/cm3 |

| True Density: | ≥3.6g/cm3 |

| Bulk density(LPD): | 1.53-1.99 g/cm3 |

| Color: | Brown |

| Particle shape: | Trigonal |

| Available grits | |

| Grain for bonded abrasive (P graded grain) | 8-80# |

| 90-150# | |

| 180-240# | |

| Grain for coated abrasive (F graded grain) | 8-80# |

| 100-150# | |

| 180-220# | |

*customized sizes are available upon request.