Green Silicon Carbide is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke. It is a synthetic brittle carborundum with high thermal conductivity and high strength which get no decrease in 1000℃( 7.5 times stronger than Alumina)

Green silicon carbide is characterized with extreme hardness (Mohs 9.4/2600 Knoop) which only rank after CBN and B4C.

Characteristic:

Low density

Low thermal expansion, oxidation resistance

Excellent chemical resistance

High thermal shock resistance

High wear and hardness resistance

High strength, high temperature resistance

High temperature strength

Applications:

Blasting, surface Treatment for glass, ceramic, etc.

Cosmetics products manufacturing, beauty crafts and dermabrasion etc.

Ceramic products

Raw material of GC grinding wheel, sandpaper, abrasive cloth suitable for marble and granite.

Grinding hard alloy ,non-ferrous metal, plastic, etc.

Raw material of Whetstone, oilstone, grinding stone, abrasive stones and so on

| TYPICAL CHEMICAL ANALYSIS | |

| SiC | 99.05% |

| SiO2 | 0.20% |

| F,Si | 0.03% |

| Fe2O3 | 0.10% |

| F.C | 0.04% |

| TYPICAL PHYSICAL PROPERTIES | |

| Hardness: | Mohs:9.4 |

| Specific Gravity: | 3.2g/cm3 |

| Bulk density(LPD): | 1.2-1.6 g/cm3 |

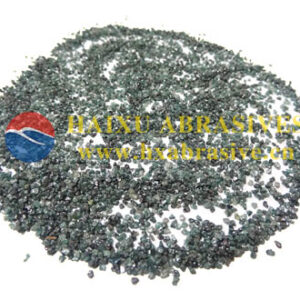

| Color: | Green |

| Particle shape: | Hexagonal |

| Melting Point: | Dissociated at about 2600 ℃ |

| Maximum service temperature: | 1900℃ |

| Friability | Friable |

| AVAILABLE SIZES | |

| 4# 5# 6# 8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# | |