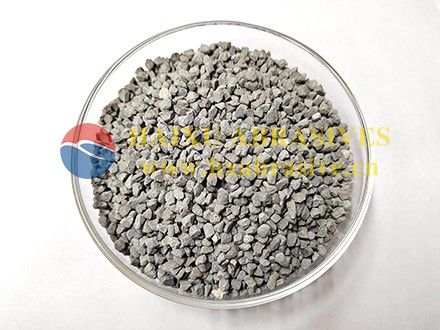

40% alumina-zirconia grains with good shape is suitable for making heavy duty grinding wheel,centerless grinding wheels for it’s long worktime. It is made of high-purity alumina and zirconium material as raw materials. After high temperature smelting at 2250℃, it is formed by special processing technology and Barmac ball milling. It has high quality, extremely hard, compact structure and special crystals, dendritic eutectic structure. According to the content of ZrO2, zirconium corundum can be divided into ZA25 zirconium corundum (ZrO225%) and ZA40 zirconium corundum (ZrO2 40%).

The biggest feature of zirconium corundum that is different from ordinary corundum and silicon carbide is superior self-sharpening, toughness and wear resistance. Used for making grinding wheels, it can significantly improve the life and sharpness of grinding wheels, and for grinding and cutting workpieces with higher hardness, the wear resistance is particularly obvious. Mainly used in the production of heavy-duty grinding wheels, resin grinding wheels, cutting discs, wear-resistant products, high-end abrasive tools, etc., suitable for steel parts, cast iron parts, heat-resistant steel, titanium alloys, nickel alloys, aluminum alloys, tungsten titanium alloys and other materials The grinding force is higher than that of ordinary corundum products.

Characteristic of 40% alumina-zirconia grains with good shape :

1. The toughness of Zirconia is very high, about 13-15 times that of brown aluminum oxide.

2. The crystal size of zirconia is very small (HAIXU ordinary quality crystal size is 18-20um, HAIXU high-quality crystal size is 10-12um), which is one-twentieth of the ordinary electron fused alumina. The smaller crystal size can continuously produce small sharpness edges during grinding. So the service life is improved.

3. The bulk density of zirconia is high (1.9-2.45g/cm3), while the bulk density of ordinary fused corundum such as white aluminum oxide and brown aluminum oxide is 1.55-1.95g/cm3. Zirconia alumina is suitable for the production of high-speed grinding wheels, heavy-duty grinding wheels, and cutting discs and other abrasive tools.

Application of Zirconia fused aluminum oxide ZA25 F8 :

1. Bonded Abrasives:

Used to produce heavy-duty grinding wheels, barren grinding wheels, rail snagging & grinding wheel, cutting disc, and high-grade resin bonded grinding wheels,centerless grinding wheel.

Abrasive Disc for grinding and cutting difficult to grind materials.

Raw material for high-end production of cutting discs, grinding discs, polishing wheels, etc.

2. Coated Abrasives:

Used to produce coated abrasives, such as sandpaper, abrasive belts, flexible polishing wheels, etc., to improve polishing accuracy and work efficiency.

3. Used to produce wear-resistant hammers, wear-resistant rollers and other wear-resistant products.

4. Abrasive sandblasting and surface treatment, suitable for marble, super hard steel and other materials.

5. Used for high-level refractory materials to make zirconia refractory bricks, etc.

Technical data of 40% alumina-zirconia grains with good shape :

| Chemical composition | ||

| Item | ZA25 | ZA40 |

| AL2O3 | 70-72% | 55-57% |

| ZrO2 | 24-30% | 35-44% |

| TiO2 | Max 1.0% | Max 0.8% |

| Fe2O3 | Max 0.3% | Max 0.25% |

| SiO2 | Max 0.8% | Max 0.6% |

| Typical physical properties | ||

| Item | ZA25 | ZA40 |

| Specific Gravity | 4.30g/cm3 | 4.60g/cm3 |

| Bulk density(LPD) | 1.90-2.30g/cm3 | 2.15-2.45g/cm3 |

| Knoop hardness | 1600 | 1450 |

| Melting Point | 1950℃ | 1900℃ |

| Particle shape | Monoclinical tetragonal | |

| Chemical property | Amphoteric | |

| Reaction with acid and alkali | NO | |

| Reaction with carbon | Forming carbide since 1650 ℃ | |

| Crystal Size | ≤30 μm | |

| Maximum service temperature | 1600 ℃ | |

| Color | Gray | |

| Specific heat capacity(cal/g.C) | 0.2205(50-500℃) | |

| Heat conductivity | 0.2718 cal/cm2.sec.℃ | |

| Linear expansivity(X10-6) | 6.82(100-700℃) | |

Available sizes:

| F-Grit(For Bonded Abrasives with high LPD) | F6 F8 F10 F12 F14 F16 F20 F22 F24 F30 F36 F40 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220 |

| F-Grit(For sandblasting) | F6 F8 F10 F12 F14 F16 F20 F22 F24 F30 F36 F40 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220 |

| P-Grit(For Coated Abrasives) | 60# 70# 80# 90# 100# 120# 150# 180# 220# 240# 320# 360# 400# 500# 600# 800# |

| Section Sand and Fine Powder(For Refractory) | 0-0.5mm,0-1mm,1-3mm,3-5mm,5-8mm,100#-0,200#-0,320#-0 |

Available Sizes and Bulk Denstiy

| ZA25 F-Grit Size | Bulk density (g/cm3) |

| F8 | 2.24-2.32 |

| F10 | 2.19-2.26 |

| F12 | 2.16-2.24 |

| F14 | 2.14-2.19 |

| F16 | 2.12-2.18 |

| F20 | 2.03-2.16 |

| F22 | 2.02-2.13 |

| F24 | 2.00-2.10 |

| F30 | 1.97-2.06 |

| F36 | 1.95-2.02 |

| F40 | 1.93-1.99 |

| F46 | 1.90-1.98 |

| F54 | 1.88-1.96 |

| F60 | 1.86-1.94 |

| F70 | 1.83-1.92 |

| F80 | 1.81-1.89 |

| ZA40 F-Grit Size | Bulk density (g/cm3) |

| F8 | 2.34-2.38 |

| F10 | 2.28-2.32 |

| F12 | 2.26-2.30 |

| F14 | 2.24-2.28 |

| F16 | 2.18-2.24 |

| F20 | 2.15-2.21 |

| F22 | 2.12-2.18 |

| F24 | 2.09-2.15 |

| F30 | 2.00-2.12 |

| F36 | 1.99-2.10 |

| F40 | 1.96-2.08 |

| F46 | 1.91-2.05 |

| F54 | 1.87-2.03 |

| F60 | 1.83-2.00 |

| F70 | 1.80-1.97 |

| F80 | 1.76-1.89 |

Reshaped high LPD Zirconia Aluminum Oxide

| Bulk density (g/cm3) | ||

| ZA25 | ZA40 | |

| F6 | 2.38-2.43 | / |

| F8 | 2.36-2.43 | / |

| F10 | 2.35-2.43 | / |

| F12 | 2.35-2.40 | 2.35-2.45 |

| F14 | 2.34-2.40 | 2.32-2.40 |

| F16 | 2.04-2.38 | 2.32-2.40 |

| F20 | 2.30-2.37 | 2.29-2.39 |

| F22 | 2.26-2.35 | 2.28-2.38 |

| F24 | 2.28-2.34 | 2.28-2.38 |

Production of 40% alumina-zirconia grains with good shape :

Package of 40% alumina-zirconia grains with good shape :

1. 1MT in a jumbo bag with rings.

2. 25 KGS in a PVC Bag,then 40 bags in a jumbo bag.

3. 25 kgs in paper bag, then 40 bags in a pallet.

4. Customized package are available.