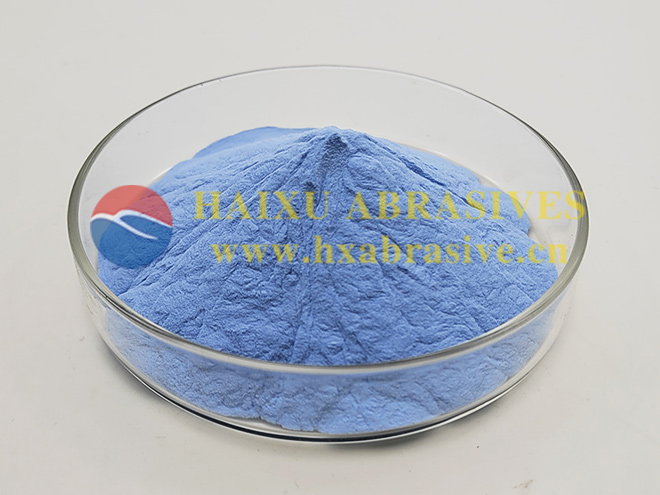

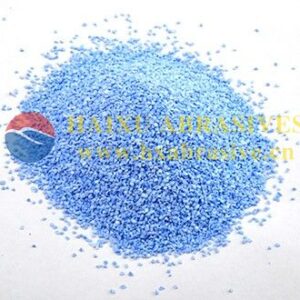

Ceramic Alumina Abrasive powder F240-F600

Introduction of Ceramic Alumina Abrasive powder F240-F600

Ceramic Alumina Abrasive powder F240-F600 is made by sol-gel process. Ceramic abrasives powder is extremely hard and durable compared to traditional aluminum oxide abrasive materials. It is suitable for bonded grinding tools and coated grinding tools.

Ceramic Alumina powder is particularly used for casting steel grinding under high pressure, as well as precision grinding of various materials, including gear grinding, bearing grinding, crankshaft grinding, rolling mill grinding, and others.

The features of Ceramic Alumina Abrasive powder:

- Tiny crystal size of nano size. That caused sharp grinding and less sparkle.

- Excellent self-sharpening performance.

- High hardness

- Extreme high toughness.

Physical properties of Ceramic Alumina Abrasive powder:

| Product Name | SG Blue Ceramic Alumina Abrasive |

| Method | Sol-Gel |

| True Density | ≥3.90 g/cm³ |

| Hv Hardness | 2100-2200(khf/mm³) |

| Color | Blue |

| Crystal size | 50-150nm |

| Roughness | 65% |

Chemical composition of Ceramic Alumina Abrasive powder:

| AL2O3 | 94-99% |

| Y2O3 | 1-2% |

| La2O3+NdO2 | 2-3% |

| MgO | 1-3% |

Applications of Ceramic Alumina Abrasive powder:

Ceramic Alumina Abrasive powder always mixed with other abrasive grains to make abrasive tools.

- Diamond cutting wheel.

- Coated abrasives.

- Diamond vitrified gear grinding wheel.

- High level resin boned grinding wheel.

- High level vitrified bonded grinding wheel.

- Centerless grinding wheel.

- High level cutting disc.

- High level coated abrasives.

Available size of ceramic alumina abrasive powder:

| MICROGRITS | |

| Grit designation | Mean grain size ds50-value in μm |

| F 230 | 53.0 ± 3 |

| F 240 | 44.5 ± 2 |

| F 280 | 36.5 ± 1.5 |

| F 320 | 29.2 ± 1.5 |

| F 360 | 22.8 ± 1.5 |

| F 400 | 17.3 ± 1 |

| F 500 | 12.8 ± 1 |

| F 600 | 9.3 ± 1 |

| F 800 | 6.5 ± 1 |

| F 1000 | 4.5 ± 0.8 |

| F 1200 | 3.0 ± 0.5 |

| MICROGRITS JIS STANDARD | |

| Grit Size | Mean grain size ds50-value in μm |

| JIS240 | 63.5±3.0 |

| JIS280 | 56.0±3.0 |

| JIS320 | 47.0±3.0 |

| JIS360 | 42.0±2.0 |

| JIS400 | 34.0±2.0 |

| JIS500 | 31.0±1.5 |

| JIS600 | 27.0±1.5 |

| JIS700 | 21.0±1.0 |

| JIS800 | 16.0±1.0 |

| JIS1000 | 14.0±1.0 |

| JIS1200 | 11.5±1.0 |

| JIS1500 | 9.0±1.0 |

| JIS2000 | 7.0±1.0 |

| JIS2500 | 5.0±1.0 |

| JIS3000 | 4.0±0.5 |

| JIS4000 | 3.0±0.5 |

| P-microgrits sizes coated | |

| Grit designation | Mean grain size ds50-value in um |

| P240 | 58.2±2 |

| P280 | 52.2±2 |

| P320 | 46.2±1.5 |

| P360 | 40.5±1.5 |

| P400 | 35.0±1.5 |

| P500 | 30.2±1 |

| P600 | 25.8±1 |

| P800 | 21.8±1 |

| P1000 | 18.3±1 |

| P1200 | 15.3±1 |

| P1500 | 12.6±1 |

| P2000 | 10.3±0.8 |

| P2500 | 8.4±0.5 |