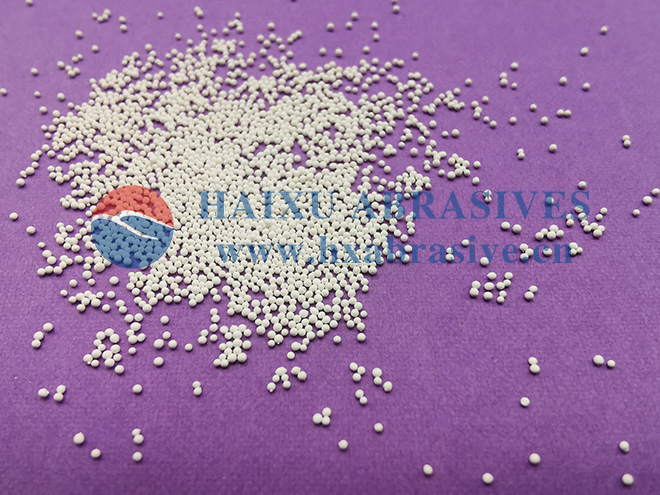

Ceramic shot microsphere Z210 for shot peening

Peening media ceramic shot is a zirconium oxide base ceramic bead. The quality of ceramic shot is coincide with SAE AMS 2431-7. It is especially suitable for aero plane and aerospace part peening and getting specific shapes. The ceramic shot can improve aero parts strength by removing prestress of aerospace components and forming the profile. It can also improve fatigue resistance and hence mechanical strength.

Characteristics of Ceramic shot microsphere Z210 for shot peening:

- High strength and wear resistance.

- Very high hardness and density. The ceramic shot has high hardness, with Vickers hardness (microhardness) of 700hv and Rockwell hardness of 60hrc.

- No dust, high abrasion resistance, and strength make it difficult for the ceramic shot to be broken during shoting.

- Sandblasting effect: the surface finish is high. Using ceramic shot sandblasting can achieve smooth satin surface brightness.

- High sandblasting efficiency and long service life

- Good roundness and spherical shape.

Chemical composition of Ceramic shot microsphere Z210 for shot peening:

| Chemical | Typical value(%) | Value range(%) |

| ZrO2 | 63.80 | 60-70 |

| SiO2 | 26.82 | 28-33 |

| AL2O3 | 9.08 | Max 10 |

| Fe2O3 | 0.03 | Max 0.1 |

| TiO2 | 0.24 | Max 0.4% |

Physical features of Ceramic shot microsphere Z210 for shot peening:

| Mohs Hardness | 7.0 |

| Vickers Hardness/ Rockwellhardness | 700HV/60HRC |

| Specific gravity | 3.85g/cm3 |

| Bulk density | 2.2-2.3g/cm3 |

Specification (According to SAE AMS 2431-7)

| Specification | Particle size range |

| Z100 | 100-150 um |

| Z150 | 150-210 um |

| Z210 | 210-300 um |

| Z300 | 300-425 um |

| Z425 | 425-600 um |

| Z600 | 600-850 um |

| Z850 | 850-1180 um |

*Other customized sizes are available.

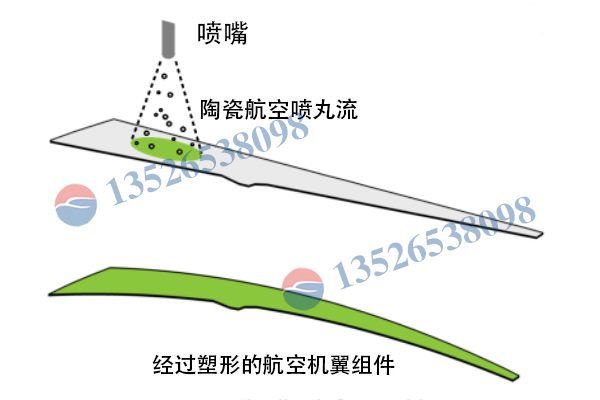

Applications of Ceramic shot microsphere Z210 for shot peening:

- Used for shot peening forming of horizontal and vertical tail wings of aircraft, and shot peening strengthening of fuselage skin structural components. Improving the fatigue life of parts

- Used for surface shot peening strengthening of high-temperature and high load single crystal blades, effectively suppressing the propagation of microcracks and pitting corrosion on the blade surface. Can improve the fatigue life of aircraft engine blades by over 20%

- Used for aircraft to strengthen the landing gear with high-strength steel shot peening, effectively improving the surface hardness and residual compressive stress of the landing gear. Commonly used for secondary shot peening to reduce the surface roughness of the landing gear.