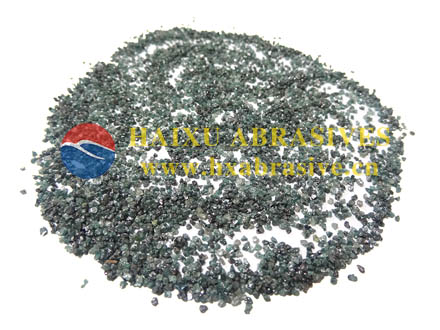

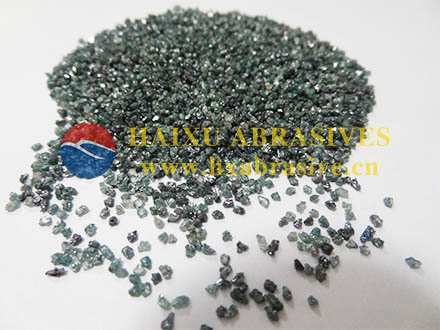

Green Silicon Carbide is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke. It is a synthetic brittle carborundum with high thermal conductivity and high strength which get no decrease in 1000℃( 7.5 times stronger than Alumina)

Green silicon carbide is characterized with extreme hardness (Mohs 9.4/2600 Knoop) which only rank after CBN and B4C.

Characteristic:

Low density

Low thermal expansion, oxidation resistance

Excellent chemical resistance

High thermal shock resistance

High wear and hardness resistance

High strength, high temperature resistance

High temperature strength

Applications:

Blasting, surface Treatment for glass, ceramic, etc.

Ceramic products

Raw material of GC grinding wheel, sandpaper, abrasive cloth suitable for marble and granite.

Grinding hard alloy ,non-ferrous metal, plastic, etc.

Raw material of Whetstone, oilstone, grinding stone, abrasive stones and so on.

| TYPICAL CHEMICAL ANALYSIS | |

| SiC | 99.05% |

| SiO2 | 0.20% |

| F,Si | 0.03% |

| Fe2O3 | 0.10% |

| F.C | 0.04% |

| TYPICAL PHYSICAL PROPERTIES | |

| Hardness: | Mohs:9.4 |

| Specific Gravity: | 3.2g/cm3 |

| Bulk density(LPD): | 1.2-1.6 g/cm3 |

| Color: | Green |

| Particle shape: | Hexagonal |

| Melting Point: | Dissociated at about 2600 ℃ |

| Maximum service temperature: | 1900℃ |

| Friability | Friable |

| AVAILABLE SIZES | |

| 4# 5# 6# 8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# | |