Introduction of Sol-gel aluminum oxide for abrasive wheels

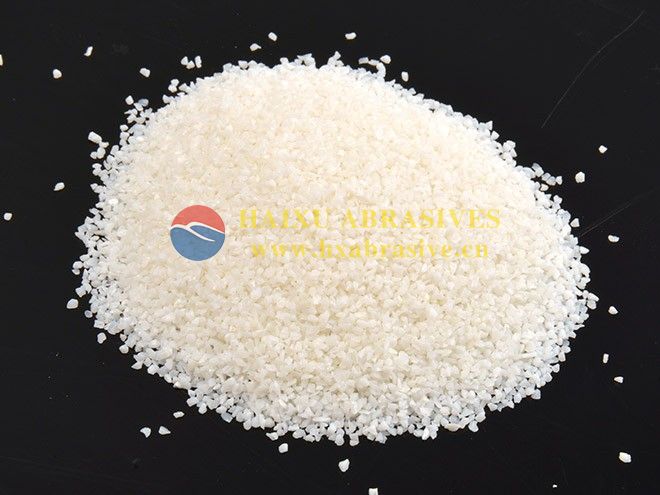

Ceramic Alumina abrasive grain is featured for its extream tiny crystal size and durability.It is also be called SG abrasive grain or ceramic alumina. Ceramic alumina grain is made by a sol-gel method instead of fusing process. The main structure of ceramic alumina grain isα-Al2O3. White color and blue color sol-gel alumina grains are made from different seeded formulas. The white one is of higher aluminum oxide purity. And white color is more suitable for vitrified boned abrasive wheels.

The features of Sol-gel aluminum oxide for abrasive wheels

1. Small crystal size about 100-150nm, which is even much smaller than zirconia alumina. And it’s hundredths of the size of normal fused alumina grains.So it will make abrasive wheels increase lifetime by several times than ordinary wheels.

2. Excellent self-sharpening performance. The sol-gel grain will get new grinding edges after grinding. The edges are get from the single grain crystal instead of off a whole crystal. That makes the grain much sharper than normal fused alumina.

3. The microscopic hardness of sol-gel alumina is about 1900-2400 kgs/cm2,which is higher than zirconia alumina. Thus,sol-gel alumina can make grinding and cutting easier for special hard metal such as Nickel chromium alloy and nickel titanium alloy.

4. The roughness is double of normal fused alumina,and even higher than zirconia alumina.

5. Low temperature grinding is another significant property of Sol-gel alumina abrasive grain. That will avoid much heat during grinding and cutting, so it won’t get hurt of workpiece surface.

6. Small size grinding edges and sharp grinding can avoid tiny crackle on workpiece.

Physical properties of Sol-gel aluminum oxide for abrasive wheels

| Product Name | SG Ceramic Alumina Abrasive |

| Method | Sol-Gel |

| True Density | ≥3.90 g/cm³ |

| Hv Hardness | 2100-2200(khf/mm³) |

| GPa hardness | 21-21.5Gpa |

| Color | White |

| Crystal size | 100-150nm |

| Roughness | 65% |

Chemical composition of Sol-gel aluminum oxide for abrasive wheels

| AL2O3 | Min. 99.4% |

| TiO2 | Max. 0.2% |

| SiO2 | Max. 0.08% |

| Fe2O3 | Max. 0.02% |

| Na2O | Max. 0.1% |

Applications of Sol-gel aluminum oxide for abrasive wheels

Sol-gel alumina abrasive grain always mixed with other abrasive grains to make abrasive tools.

1. Diamond cutting wheel.

2. Diamond vitrified gear grinding wheel.

3. High level resin boned grinding wheel.

4. High level vitrified bonded grinding wheel.

5. Centerless grinding wheel.

6. High level cutting disc.

7. High level coated abrasives.

The bulk density of Sol-gel aluminum oxide for abrasive wheels

| Grit designation | Mean diameter in um | Bulk Density(g/cm3) |

| F16 | 1230 | 1.76-2.00 |

| F20 | 1040 | 1.78-2.02 |

| F22 | 885 | 1.78-2.02 |

| F24 | 745 | 1.78-2.00 |

| F30 | 625 | 1.77-2.00 |

| F36 | 525 | 1.79-1.99 |

| F40 | 438 | 1.75-1.96 |

| F46 | 370 | 1.73-1.93 |

| F54 | 310 | 1.76-1.95 |

| F60 | 260 | 1.72-1.94 |

| F70 | 218 | 1.70-1.92 |

| F80 | 185 | 1.67-1.87 |

| F90 | 154 | 1.65-1.86 |

| F100 | 129 | 1.64-1.84 |

| F120 | 109 | 1.63-1.82 |

| F150 | 82 | 1.62-1.82 |

| F180 | 69 | 1.60-1.80 |

| F220 | 58 | 1.58-1.78 |